Table of Contents

The Process of custom polyester bandana Production

Polyester bandanas have become a popular accessory in recent years, with their versatility and durability making them a staple in many wardrobes. However, not all polyester bandanas are created equal. For those looking for a truly unique and high-quality product, custom-made polyester bandanas are the way to go.

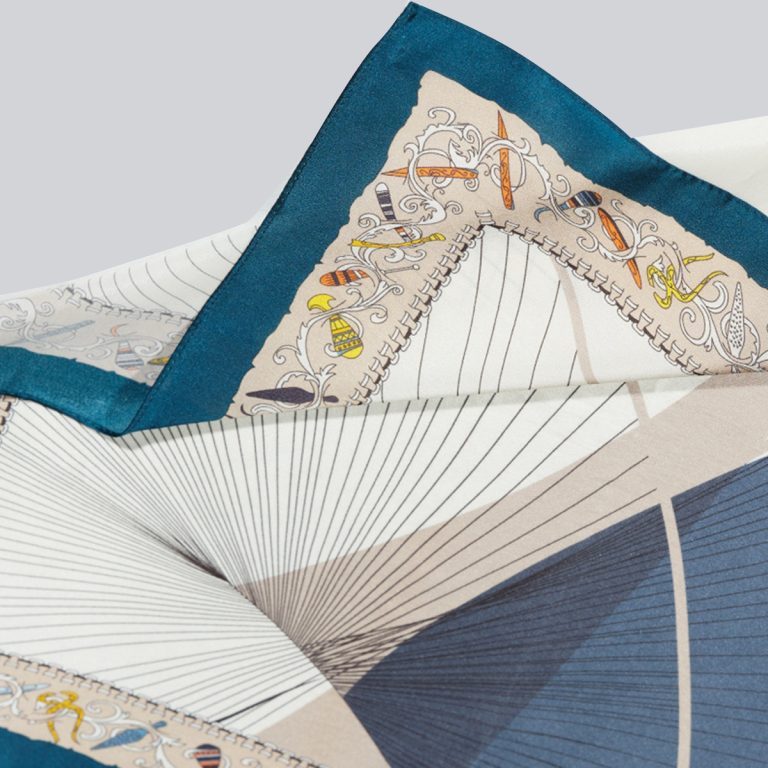

custom scarf printing and twilly companies that specialize in high-grade textiles offer a behind-the-scenes look at the intricate process of creating these custom polyester bandanas. From design to production, every step is carefully executed to ensure the final product meets the highest standards of quality.

The process begins with the selection of the fabric. High-grade polyester is chosen for its durability and vibrant color retention, ensuring that the bandana will maintain its quality over time. Once the fabric is selected, the design process begins.

Designers work closely with clients to create a custom design that reflects their unique style and vision. Whether it’s a bold graphic print or a subtle pattern, the design is carefully crafted to meet the client’s specifications. Once the design is finalized, it is sent to the printing department.

Custom scarf printing companies use state-of-the-art printing technology to transfer the design onto the fabric. This process ensures that the colors are vibrant and the details are crisp, resulting in a high-quality finished product. Once the fabric has been printed, it is carefully inspected for any imperfections before moving on to the next step.

The next step in the production process is cutting and sewing. Skilled artisans carefully cut the fabric to size, ensuring that each bandana is uniform in shape and size. The fabric is then sewn together with precision and care, creating a finished product that is both durable and stylish.

Quality control is a crucial step in the production process. Each bandana is carefully inspected for any flaws or imperfections, ensuring that only the highest quality products are sent to clients. Once the bandanas have passed inspection, they are carefully packaged and shipped to their final destination.

Custom-made polyester bandanas offer a level of quality and customization that is unmatched by mass-produced products. By working with a custom scarf printing and twilly company that specializes in high-grade textiles, clients can create a truly unique accessory that reflects their personal style and vision.

In conclusion, the process of creating custom polyester bandanas is a meticulous and intricate one. From the selection of high-grade fabric to the careful design and printing process, every step is executed with precision and care. By working with a custom scarf printing and twilly company that specializes in high-grade textiles, clients can create a truly unique and high-quality accessory that will stand the test of time.

Printing Techniques for custom scarves and Twillies

Custom made polyester bandanas, custom scarf printing, and twillies are all popular textile creations that can add a touch of style and personality to any outfit. Behind the scenes of these custom creations are companies that specialize in high-grade printing techniques to ensure quality and durability.

When it comes to custom scarf printing, there are a variety of techniques that can be used to achieve different effects. Digital printing is a popular method that allows for intricate designs and vibrant colors to be printed directly onto the fabric. This technique is ideal for custom scarves that feature detailed patterns or photographs.

Another common printing technique for custom scarves is screen printing. This method involves creating a stencil of the design and then using a squeegee to push ink through the stencil onto the fabric. Screen printing is great for custom scarves with bold, graphic designs and can create a textured finish on the fabric.

| queen size | best bandanas | affordable | silk scarf |

| 5 below scarves | silk turban | tailored | 2×4 scarf joint |

| modal mixed | hijab cap | table print | bow tie scarf |

For custom twillies, companies often use a process called sublimation printing. This technique involves printing the design onto a special paper and then using heat and pressure to transfer the design onto the fabric. Sublimation printing is ideal for custom twillies that require a full-color, all-over print.

In addition to printing techniques, companies that specialize in custom textile creations also pay close attention to the quality of the materials used. High-grade polyester is a popular choice for custom bandanas, scarves, and twillies due to its durability and versatility. Polyester is a synthetic fiber that is known for its ability to hold color well and resist wrinkles, making it an ideal choice for custom printed textiles.

Companies that specialize in custom textile creations also offer a range of finishing options to enhance the look and feel of their products. For custom scarves and twillies, companies may offer options such as hand-rolled edges, fringe detailing, or custom tags. These finishing touches can add a touch of luxury to the final product and make it stand out from mass-produced alternatives.

When choosing a company for custom made polyester bandanas, custom scarf printing, or twillies, it is important to consider their experience and expertise in the industry. Look for companies that have a proven track record of producing high-quality, custom textile creations and that use the latest printing techniques and materials.

In conclusion, custom made polyester bandanas, custom scarf printing, and twillies are all popular textile creations that can add a unique touch to any outfit. Behind the scenes of these custom creations are companies that specialize in high-grade printing techniques, quality materials, and finishing options to ensure a superior product. When choosing a company for custom textile creations, be sure to consider their experience and expertise to ensure you receive a quality product that meets your needs and expectations.